Why Is Wire So Expensive? All You Need To Know

Wire, an omnipresent element of our modern lives, often goes unnoticed despite its ubiquity. It is commonly perceived as a basic commodity, prompting curiosity about the reasons behind its seemingly high cost.

In this article, we will delve into the intricacies of wire pricing, exploring the various factors contributing to its expense.

Why Is Wire So Expensive? What effects the wire prices?

Raw Materials and Manufacturing

The significance of high-quality raw materials

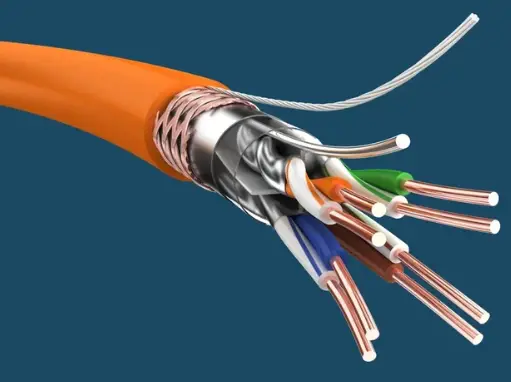

Wire primarily relies on copper as a conductor material due to its exceptional electrical conductivity. The purity and quality of copper directly influence the wire’s performance and durability. Furthermore, specialty materials such as aluminum, silver, or gold may be used in specific applications, contributing to the overall cost.

Complex manufacturing processes

The production of wire involves intricate manufacturing processes that require precision and expertise. Drawing and refining techniques, such as hot or cold rolling, ensure the wire’s desired dimensions and mechanical properties.

Additionally, wires may require insulation and shielding to meet safety and performance standards, adding to the production complexity and cost. Manufacturers also invest heavily in quality control measures to maintain consistency and reliability.

Market Demand and Supply

Increased demand in various industries

Wire is an essential component in numerous industries, driving up its demand. The construction and infrastructure sector rely on wire for electrical installations, power transmission, and telecommunications networks.

Similarly, the electronics industry requires wire for circuitry, connectors, and data transmission. Moreover, the growing adoption of renewable energy sources and electric vehicles further amplifies the demand for specialized wire products.

Supply chain challenges and their influence on pricing

The global demand for wire presents challenges in the supply chain. Fluctuations in raw material costs, such as copper, can significantly impact wire pricing. Moreover, market competition and monopolies within the wire manufacturing sector can influence the market dynamics, leading to higher prices.

Why is Romex So Expensive? A Must-Read Guide For You

rlctalk.com

Regulatory Standards and Compliance

Safety and performance requirements

To ensure safety and reliability, wire must adhere to stringent international standards and certifications. These standards define parameters for fire resistance, electrical conductivity, and insulation properties, among others.

Meeting these requirements necessitates additional research, testing, and development investments, all of which contribute to the overall cost.

Compliance costs for manufacturers

Wire manufacturers face substantial compliance costs to meet the regulatory standards. Rigorous testing and certification procedures are required to validate wire performance and safety attributes.

Furthermore, manufacturers must implement continuous quality assurance processes to maintain compliance, which adds to the overall cost.

Research and Development

Innovation driving wire technology

Ongoing research and development efforts continually drive wire technology forward. Innovations in conductor materials, such as high-temperature superconductors or composite materials, aim to enhance electrical conductivity and reduce energy losses.

Additionally, advancements in wire design focus on improving energy efficiency, miniaturization, and flexibility to meet evolving industry needs.

Investment in research and development

Investment in research and development plays a significant role in wire pricing. Exploring new materials, manufacturing techniques, and design concepts incurs substantial costs. These costs are recouped through pricing, reflecting the value of research-driven advancements.

How to choose better wires with good reliability?

Choosing reliable wires involves considering several factors. Here are some tips to help you choose better wires with good reliability:

- Determine the wire’s application

Start by understanding the purpose of the wire. Different applications have different requirements, such as electrical conductivity, insulation, flexibility, or resistance to environmental conditions.

- Assess wire gauge

The wire gauge refers to its diameter. Thicker wires generally have lower resistance and can handle higher currents. Consider the power requirements and choose an appropriate gauge to prevent overheating and voltage drop.

- Insulation material

Insulation protects wires from external factors like moisture, heat, chemicals, and abrasion. Common insulation materials include PVC, rubber, and Teflon. Ensure the wire insulation is compatible with the intended environment and meets safety standards.

- Consider wire type

Different wire types suit specific applications. For example, solid wires are suitable for fixed installations, while stranded wires are more flexible and ideal for movable parts. Research the wire types available and select the one that matches your requirements.

- Check for certifications

Look for wires that have relevant certifications from reputable organizations. Certifications like UL (Underwriters Laboratories) or CSA (Canadian Standards Association) indicate that the wire has been tested and meets specific safety and performance standards.

- Evaluate durability

Consider the wire’s durability based on your needs. If the wire will be subjected to frequent bending or physical stress, choose wires with high flexibility and resistance to breakage. Look for wires with good tensile strength and resistance to wear and tear.

- Review manufacturer reputation

Choose wires from reputable manufacturers known for producing high-quality and reliable products. Research online reviews, customer feedback, and industry recommendations to gauge the manufacturer’s reputation.

- Consider cost-effectiveness

While reliability is crucial, also consider the wire’s cost and overall value. Compare prices from different suppliers and manufacturers, ensuring that you’re getting a good balance between quality and affordability.

- Seek expert advice if needed

If you have specific requirements or are unsure about the best wire choice, consult with electrical engineers, professionals, or suppliers who have expertise in the field. They can provide valuable insights and recommendations based on your specific needs.

By considering these factors, you can choose wires that offer better reliability for your intended applications.

Which is better wire or cable?

The choice between wire and cable depends on the specific application. Wires are suitable for simple electrical connections and small-scale applications, offering flexibility and ease of installation. Cables, with their multiple bundled conductors, provide better protection against interference and are ideal for longer runs or complex systems.

They offer durability and shielding, making them suitable for harsh environments. Both have their advantages, and the better option depends on factors like flexibility, signal integrity, environmental conditions, and installation requirements. Consider the specific needs of your application to determine whether wire or cable is the better choice.

Copper For Electrical Wiring: The Science Behind It

rlctalk.com

Conclusion

Often overlooked as a basic commodity, wire is a critical component of modern infrastructure. The seemingly high cost of wire is a result of various interrelated factors. Each aspect contributes to its overall pricing, from raw materials and complex manufacturing processes to market demand and regulatory compliance. Understanding these complexities helps us appreciate the value and significance of wire in its myriad applications.